Many companies have difficulty tracking inventory with conventional technologies and tracking systems. Problems with tracking inventory lead to excess items or shortages in material supplies or products, and tracing issues can be time-consuming. Automotive companies are now actively looking for ways to improve supply chain visibility across the board so that they may have a better idea of how to manage their inventory more efficiently.

The COVID-19 pandemic has also had a disruptive effect on global supply chains. The automotive sector has particularly taken a hit with chip shortages, plant shutdowns, and the shift towards EVs that has caused a decline in fossil fuel vehicle purchases. In this article, we’ll cover the reasons why supply chain visibility is crucial to the automotive industry, and how your business can take steps to improve it.

What is Supply Chain Visibility (SCV)?

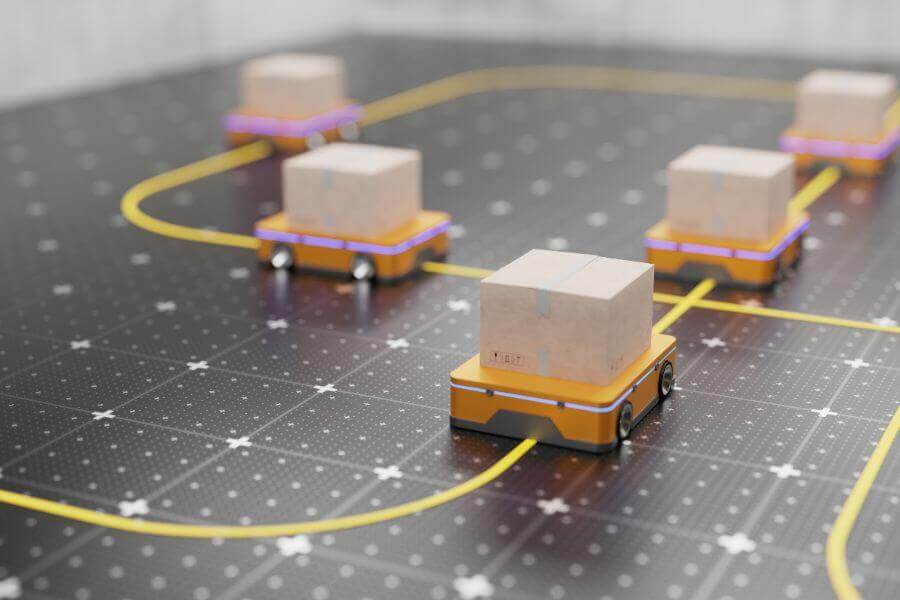

Supply chain visibility, SCV in short, refers to the concept of being able to track every item on the supply chain from its point of origin to the final destination. The final destination can be another factory for one business (the shipment of a box of engine bolts from a vendor to the factory), or a retail service outlet that requires the same bolts for repairing a car unit. What this essentially means is that any person involved in the movement of an item from point A to B can see where it is, and ensure that everyone has access to the same supply chain data.

Supply chain technology is constantly evolving due to the nature of the industry and the rising demand for companies to track their inventory in real-time through SCV. New technologies such as RFID tags are paving the way for a transparent supply chain network that provides a dynamic view of inventory supplies moving in real-time.

SCV is also enabled by software technologies that allow users to connect to a central information system and access and share supply chain data with their supply chain partners and stakeholders. For the automotive industry, software platforms go a long way in improving supply chain visibility and transparency. Even though there are many benefits of SCV for companies today, only 6% of businesses have implemented supply chain solutions that give them full visibility into the data.

Benefits of Automotive Supply Chain Visibility

1. Increased availability of financial resources

The ability to view all available items in your inventory enables your business to implement lean inventory management practices. By viewing the available spare parts and car components, you will know when you need to utilize unused parts. The visibility in the supply chain will also help you order inventory that you immediately need for manufacturing and service so that your expenses are kept to a minimum. You can then invest more of your remaining capital in other business ventures or profitable outlets. A lean inventory model also saves you the costs associated with maintaining larger warehouse storage and the staff needed to support that kind of supply chain infrastructure.

2. Increased revenue

The availability of extra financial resources through supply chain visibility, along with cost savings on better inventory management, is great for your balance sheet. Real-time information provided by SCV systems also gives you a sense of market trends which can help you plan ahead of your competitors. You will be able to identify new business opportunities faster, thanks to an improved process workflow and forecasting capabilities.

3. Minimized risk of unplanned downtime

Visibility in the supply chain allows you to quickly respond to fluctuations in inventory levels. For example, if you need components for an automotive manufacturing process, SCV allows you to know how many parts you have, and it also informs you how quickly you can get the required parts from a vendor. You can use the information to predict your demand and proactively respond to your process requirements.

4. Increased flexibility

If you share supply chain visibility with multiple vendors, you can choose a supplier who can deliver your materials faster. This is a clear benefit in case your primary vendor experiences a shortage. SCV platforms also keep you updated about risks for shipments such as peak season traffic, weather updates, supply shocks, and rising costs, which helps you to plan your routes in advance. You won’t need to reroute your deliveries, saving you premiums on shipping expenses.

5. Informed business decision-making with real-time analytics

Supply chain visibility systems provide data at a granular level that can help you create detailed reports on every order. You can visualize information in real-time, allowing you to take corrective measures promptly. Detailed reports also help you identify gaps in any of your business processes that result in delays or underutilization of materials. This information is crucial when deciding about changes that need to be made at the operational level.

6. Improved ability to negotiate

A transparent view of item deliveries through the supply chain gives you a better idea of how much material or products are available in the market. That gives you a firm grasp of the market rates and trends for key supplies. Armed with this information, you can negotiate a better deal for yourself with your suppliers.

7. Transparent audit trails

Auditing is crucial for quality review and assurance. Supply chain visibility will help you track every production and delivery process, allowing you to conduct detailed audits for all business activities. Complete and transparent audit trails help you maintain high-quality standards to manufacture competitive products.

In any business, there is always some risk of failure that can result in breakage, poor product experience, or high maintenance costs. For most companies, it’s a question of when such a risk will come to pass. The ability to retroactively view all supply chain data is invaluable in investigating such events and zeroing in on related problems.

8. Improved customer satisfaction and experience

Sometimes customer requests are received at unexpected times, and you may not always be ready to respond. That being said, complete supply chain visibility means that you will likely have a reasonable amount of supplies in hand to respond to routine customer requests. A transparent supply chain model will facilitate getting products delivered and replaced in the least amount of time.

However, in cases where you are unable to fulfill customer requests immediately, you will also be able to give customers an ETA in case of delays. This is important for managing customer expectations and keeping customers satisfied and happy. You can also point these requests to potential suppliers who may be able to fulfill them instantly. Therefore, a complete picture of the supply chain improves your ability to handle customer requests and build trust with your target market.

Experience is Key

While there are concrete benefits to supply chain visibility, working with an experienced 3PL partner like Logos Logistics will significantly boost your business productivity. You will be able to access a range of logistics solutions that can be tailored to your transportation needs. As one of the leading 3PL providers in the Midwest, we’re well-positioned to maximize the value you can get from your automotive supply chain logistics pipelines.

Contact us today for more details.