Whether you’re running an ecommerce store, a large retail chain, or a manufacturing business, logistics is likely one of your biggest expenses. managing transportation, warehousing, inventory, and shipping can quickly become overwhelming and costly when handled in-house.

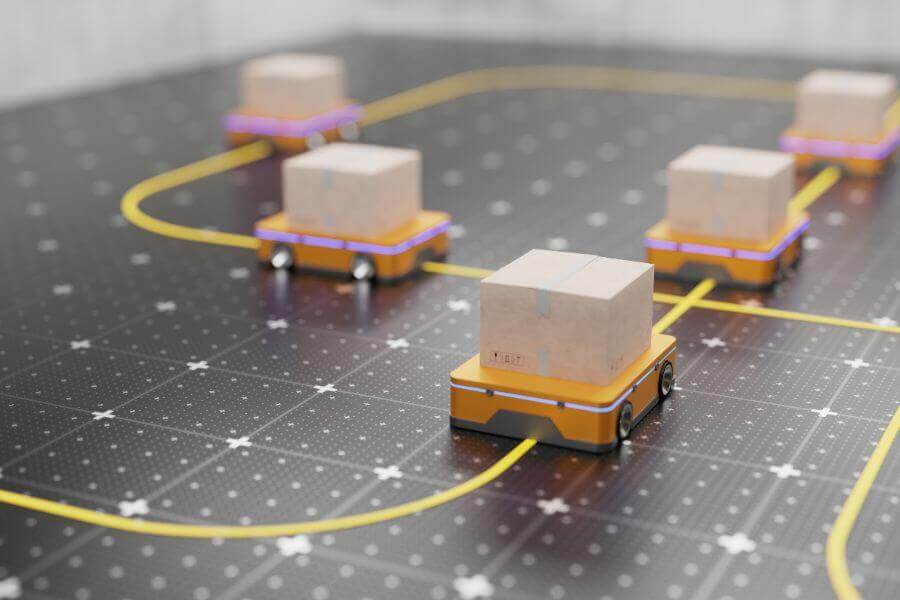

Enter third-party logistics (3PL) providers. A 3PL can take over key elements of your supply chain, including warehousing, distribution, transportation, and sometimes even value-added services such as product assembly and kitting. By outsourcing logistics to a 3PL, companies can tap into their expertise, scale up without massive investments, and access advanced technologies – all while saving substantial amounts of money.

In this article, we’ll explore 10 ways 3PLs help businesses save money and how they provide value beyond just cost reduction.

1. Lower shipping costs by leveraging bulk discounts and smarter routes

One of the most significant ways 3PLs help businesses save money is by reducing shipping costs. Shipping is often one of the most substantial expenses in logistics, particularly for businesses that deal with high volumes or complex distribution networks.

3PLs have an advantage because they manage shipping for multiple clients, which means they can consolidate shipments and use their volume to negotiate bulk discounts with carriers. These discounts aren’t available to most businesses on their own, especially smaller companies that may not have enough shipment volume to get favorable rates.

Beyond cost negotiation, 3PLs use advanced logistics software to optimize shipping routes and methods. By analyzing factors such as delivery windows, traffic patterns, and fuel costs, they determine the most efficient routes for your shipments. They might consolidate multiple orders into a single shipment or choose the most cost-effective carriers, saving you time and money. This optimization reduces not only the cost of shipping but also the potential for delays, customer dissatisfaction, and returns.

Real-world example

Consider a mid-sized ecommerce business that ships internationally. Handling its own international shipping would involve negotiating rates with several carriers, dealing with customs regulations, and managing international returns. A 3PL, on the other hand, simplifies this process by handling all of these elements and passing along their discounted international rates, saving the business both time and significant shipping expenses.

2. Lower warehouse and storage costs

Owning and managing your own warehouse comes with considerable costs, from purchasing or leasing the space to maintaining it, staffing it, and ensuring it meets regulatory requirements. Building and maintaining warehousing infrastructure also ties up capital that could be better invested elsewhere in your business.

By working with a 3PL, you can eliminate most of these costs. 3PLs typically operate large, strategically located warehouses that serve multiple clients, allowing you to share the cost of warehouse space with other companies. This arrangement means you only pay for the space and services you actually use, whether it’s storing a few pallets of goods or hundreds of thousands of units.

Additionally, 3PLs offer flexibility. Suppose your business has seasonal fluctuations in demand. In that case, a 3PL allows you to increase or decrease your storage space as needed, avoiding the fixed costs associated with leasing or owning a warehouse. This scalability ensures you aren’t paying for unused space during slow periods.

Real-world example

A growing retailer that experiences a surge in demand during the holiday season would need to expand its warehouse space to accommodate additional inventory. If they owned the warehouse, this would mean either leasing extra space or building a new warehouse – both costly options. By using a 3PL, the retailer can rent additional space during peak season and scale back during slower months, avoiding long-term fixed costs.

3. Optimized inventory management

Proper inventory management is critical to both customer satisfaction and cost control. Overstocking ties up valuable capital in unsold inventory and results in high storage costs, while understocking can lead to stockouts, lost sales, and unhappy customers. Striking the perfect balance between the two is a challenge that many businesses struggle with.

3PLs can help with this balance by using advanced inventory management systems (IMS) to monitor your stock levels in real time. These systems offer detailed visibility int your inventory, allowing you to maintain optimal stock levels and ensure products are available when needed, but not overstocked. This level of control and insight helps reduce carrying costs, minimize waste, and lower the risk of stockouts, all of which contribute to significant savings.

Moreover, many 3PLs integrate with ecommerce platforms and marketplaces, automating the reordering process when inventory falls below a certain threshold. This automation reduces human error and ensures that orders are processed efficiently and on time.

Real-world example

An online retailer that sells clothing often experiences sudden spikes in demand based on trends or seasons. By using a 3PL with advanced inventory management systems, the retailer can better predict and react to demand changes, ensuring it doesn’t overstock or understock items. This not only saves money on storage but also maximizes sales potential by preventing stockouts.

4. Efficient returns management (reverse logistics)

Handling product returns can be an expensive and time-consuming process, particularly for businesses with high return rates like ecommerce companies. Returns management, also known as reverse logistics, involves receiving, inspecting, repackaging, and restocking products, which requires additional labor and warehouse space.

3PLs can help reduce the costs associated with returns by streamlining the process. Many 3PLs specialize in reverse logistics, providing dedicated teams and processes to handle returned goods efficiently. They inspect returned items, determine whether they can be resold, and handle any necessary refurbishment or repackaging. This not only reduces the time and labor costs involved in managing returns but also ensures that returned products are processed and restocked more quickly, allowing you to recoup value from them faster.

Furthermore, outsourcing returns to a 3PL reduces the need to hire and train specialized staff for these tasks, which can be particularly beneficial for businesses that experience fluctuations in return volumes.

Real-world example

An electronics retailer that receives a high volume of returns due to product defects or buyer remorse can save significantly by outsourcing reverse logistics to a 3PL. The 3PL can efficiently process returns, refurbish or repackage items, and restock them, helping the retailer recover costs and reduce waste.

5. Avoidance of large capital investments

Building and maintaining logistics infrastructure – whether it’s warehouses, transportation fleets, or advanced software systems – requires significant capital investment. This can strain your cash flow, especially for smaller and medium-sized businesses. By outsourcing your logistics to a 3PL, you can avoid these large upfront costs.

Instead of investing in physical infrastructure, technology, or vehicles, you pay only for the services you need when you need them. This shifts logistics from a fixed cost (buying, building, or leasing assets) to a variable cost, giving you much more flexibility and financial freedom. It also allows you to reinvest capital into other areas of your business, such as research and development, marketing, or expanding your product line.

Real-world example

A consumer goods manufacturer looking to expand its operations into new markets would need to invest in new warehouses, hire logistics staff, and potentially purchase new vehicles to support distribution. By partnering with a 3PL, the manufacture avoids these capital expenses, allowing them to expand faster and more cost-effectively by leveraging the 3PL’s existing infrastructure.

6. Improved labor efficiency

Labor can be a major cost driver in logistics, particularly when it comes to warehousing and transportation. Hiring, training, and managing logistics personnel can be time-consuming and expensive. Additionally, fluctuations in demand can make it difficult to manage staffing levels efficiently – during peak seasons, you might need to hire temporary workers, while during slow periods, you might have too many employees on the payroll.

3PLs solve this issue by providing skilled labor as part of their service. Their staff are experienced in logistics operations, including order picking, packing, shipping, and inventory management. By outsourcing these tasks, you can reduce the need for in-house logistics staff and avoid the costs associated with hiring, training, and managing them.

Additionally, because 3PLs operate at scale, they can handle seasonal fluctuations in demand more efficiently. During peak times, they can ramp up staffing to ensure orders are fulfilled on time, while during slower periods, they can scale back without the need for layoffs or idle workers.

Real-world example

A toy company that experiences a significant increase in orders during the holiday season would need to hire temporary workers to meet demand. However, by working with a 3PL, the company can tap into the 3PL’s existing labor force without the hassle and costs associated with recruiting and training temporary staff.

7. Access to advanced technology and automation

Keeping up with the latest technology in logistics is not only expensive but also requires ongoing updates and maintenance. 3PLs invest heavily in state-of-the-art logistics technologies that are often out of reach for many businesses. These technologies include:

- Warehouse Management Systems (WMS). Helps track inventory levels, manage orders, and optimize warehouse layouts.

- Transportation Management Systems (TMS). Optimizes shipping routes, consolidates shipments, and selects the best carriers based on cost and speed.

- Order Fulfillment Automation. Uses robotics, conveyor systems, and other automation tools to reduce the time and labor required to pick, pack, and ship products.

- Real-Time Tracking & Analytics. Provides real-time visibility into inventory and shipments, allowing businesses to make data-driven decisions that reduce costs.

By outsourcing to a 3PL, you gain access to these advanced systems without the need to purchase or maintain them. This results in cost savings as well as improved efficiency, faster order fulfillment, and better customer satisfaction.

Real-world example

An apparel company that ships thousands of orders per day can benefit from 3PL’s automated order fulfillment systems, which use robotics and AI to speed up the picking and packing process. This reduces labor costs and ensures faster, more accurate shipping, leading to happier customers and fewer returns.

8. Scalability and flexibility for growth

One of the biggest challenges for growing businesses is calling their logistics operations to meet demand. During periods of rapid growth, businesses may struggle to keep up with orders, while during slower periods, they may find themselves overstaffed or paying for underutilized warehouse space. This mismatch can lead to unnecessary costs and lost sales.

3PLs offer scalability and flexibility that can help businesses navigate these fluctuations. Because they manage logistics for multiple clients, they can easily scale services up or down as your needs change. Whether you’re launching a new product, expanding into new markets, or dealing with seasonal surges, a 3PL can provide the additional warehousing, transportation, and labor you need to meet demand without the fixed costs of expanding your in-house logistics capabilities.

This flexibility allows businesses to stay nimble, adjust to market conditions, and scale more efficiently, all while controlling costs.

Real-world example

A small electronics manufacturer that experiences surges in demand when releasing new products can quickly scale up its logistics operations by partnering with a 3PL. The 3PL provides the additional warehousing, transportation, and fulfillment capacity needed during the product launch, allowing the manufacturer to focus on production and marketing without worrying about logistics bottlenecks.

9. Risk reduction and liability management

Managing logistics in-house comes with numerous risks, including the potential for shipping delays, damaged goods, regulatory compliance issues, and disruptions caused by market volatility. These risks can lead to costly disruptions, fines, or damage to your brand’s reputation.

3PLs are experts in managing logistics risks. They have contingency plans in place to deal with common issues such as weather disruptions, customs delays, or carrier breakdowns. They also stay up-to-date on the latest regulations and compliance requirements, ensuring your shipments meet all necessary legal standards.

Many 3PLs also offer insurance options to protect your goods in transit, further reducing your financial exposure in the event of a loss or damage. By outsourcing logistics to a 3PL, you transfer some of these risks to them, protecting your business from unexpected costs and liabilities.

Real-world example

A pharmaceutical company that ships sensitive, high-value products internationally faces numerous risks, including temperature control, customs delays, and regulatory compliance. By partnering with a 3PL that specializes in pharmaceutical logistics, the company can ensure that its products are handled properly and reduce the risk of costly disruptions or regulatory violations.

10. Access to industry expertise and best practices

The logistics industry is complex and constantly evolving, with new technologies, regulations, and best practices emerging regularly. Keeping up with these changes can be challenging for businesses that don’t specialize in logistics. By partnering with a 3PL, you gain access to their deep industry expertise and best practices.

3PLs are constantly optimizing their processes to reduce costs and improve efficiency. They stay current on the latest trends in transportation, warehousing, and inventory management, ensuring that your logistics operations are always cutting-edge. This expertise helps businesses avoid costly mistakes, comply with regulations, and stay competitive in a fast-moving market.

Moreover, many 3PLs offer consultative services, helping businesses identify areas for improvement in their supply chain and providing actionable insights to reduce costs and improve efficiency.

Real-world example

A company expanding into international markets would benefit from a 3PL’s expertise in navigating complex customs regulations, trade agreements, and shipping requirements. The 3PL’s knowledge helps the company avoid costly delays and fines, ensuring smooth international operations.

Conclusion

Partnering with a 3PL can transform your logistics operations and lead to substantial cost savings. Whether it’s reducing shipping expenses, optimizing inventory, or scaling your business without massive capital investment, a 3PL offers flexibility and expertise that’s hard to match with in-house operations. If logistics are becoming a pain point for your business, or if you’re just looking to cut costs and improve efficiency, working with a 3PL may be a smart move.

By taking advantage of a 3PL’s infrastructure, technology, and expertise, you can focus more on what matters – growing your business and serving your customers.