The logistics industry is changing fast. In 2025, new technologies are making big changes to how goods move around the world. Let’s look at 10 exciting technologies that are shaping the future of logistics.

1. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are becoming very important in logistics. These smart computer systems can think and learn like humans, but much faster.

In 2025, AI is helping logistics companies in many ways:

- It can predict when products will be needed, so companies always have the right amount in stock.

- It can find the best routes for trucks and ships, saving time and fuel.

- It can spot problems in the supply chain before they happen, so companies can fix them quickly.

For example, AI can look at weather reports, traffic data, and past delivery times to choose the fastest and safest route for a truck. This means packages arrive on time more often.

ML is also making warehouses smarter. Robots using ML can learn how to pick and pack items more efficiently over time. They get better at their jobs every day, just like humans do.

2. Internet of Things (IoT)

The Internet of Things is a fancy name for everyday objects that can connect to the internet. In logistics, IoT devices are everywhere in 2025.

Here’s how IoT is changing logistics:

- Small sensors on packages can tell companies exactly where each item is at all times.

- These sensors can also check if food is staying cold enough or if fragile items are being handled carefully.

- In warehouses, IoT devices can automatically count stock and order more when supplies are low.

Imagine a refrigerated truck carrying fresh fruit. IoT sensors inside the truck can constantly check the temperature. If it gets too warm, they can alert the driver or even adjust the cooling system automatically. This keeps the fruit fresh and prevents waste.

3. Blockchain technology

Blockchain is like a super-secure digital notebook that can’t be changed once something is written in it. In 2025, it’s making logistics more trustworthy and efficient.

Here’s what blockchain does for logistics:

- It creates a clear record of where every product has been, from factory to store.

- It makes paperwork faster and more accurate, reducing mistakes and delays.

- It helps stop fake products by proving where real ones came from.

For instance, when you buy expensive medicine, blockchain can show you exactly where it was made and how it got to you. This gives you confidence that it’s real and safe.

4. Autonomous vehicles and drones

Self-driving vehicles and flying drones are no longer just in movies. In 2025, they’re part of everyday logistics.

Autonomous vehicles are changing transportation:

- Self-driving trucks can travel long distances without stopping, making deliveries faster.

- They don’t get tired like human drivers, so they’re safer on long trips.

- In warehouses, self-driving forklifts and carts move items around without human help.

Drones are perfect for quick deliveries:

- They can fly over traffic jams to deliver small packages in cities.

- In rural areas, drones can reach places that are hard for trucks to get to.

- They’re also great for checking on large outdoor storage areas quickly.

Imagine ordering a book online and having a drone drop it off on your balcony just an hour later!

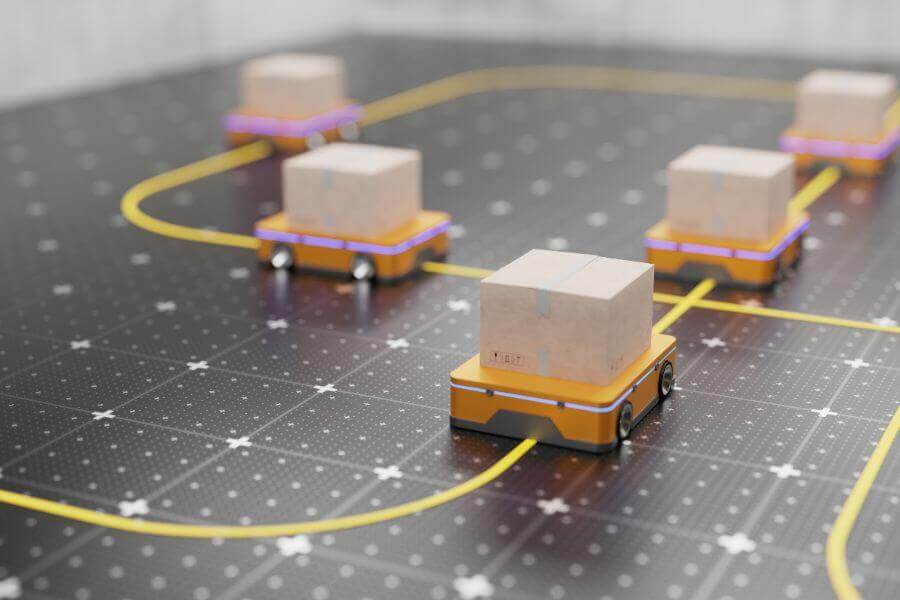

5. Advanced robotics

Robots are getting smarter and more helpful in logistics. In 2025, they’re doing jobs that used to be too complex for machines.

Here’s how advanced robots are helping:

- They can pick up and pack almost any kind of item, even oddly shaped ones.

- They work alongside humans, helping with heavy lifting and repetitive tasks.

- Some robots can even “see” and “feel,” allowing them to handle delicate items carefully.

Picture a warehouse where robots and humans work together. A robot might pick items from high shelves and bring them to a human who checks and packs them. This teamwork makes the job faster and easier for everyone.

6. 3D printing

3D printing is changing how some products are made and delivered. Instead of shipping finished products, companies can send digital files to be printed locally.

3D printing in logistics means:

- Less need to store many products, as they can be printed on demand.

- Faster delivery of spare parts, which can be printed near where they’re needed.

- Custom products can be made quickly and close to the customer.

For example, if your car needs a rare spare part, a nearby service center could 3D print it instead of waiting days for it to be shipped from far away.

7. Cloud computing and digital twins

Cloud computing means storing and using data on the internet instead of on a single computer. Digital twins are virtual copies of real things or processes.

Together, they’re making logistics smarter:

- Companies can access their data from anywhere, making it easier to work together.

- Digital twins let companies test new ideas safely before trying them in real life.

- They help predict problems and find ways to make things work better.

Imagine a big shipping port with a digital twin. Managers can use this virtual copy to try different ways of moving ships and containers around. They can find the best way to do things without disrupting real operations.

8. Augmented Reality (AR) and Virtual Reality (VR)

AR adds digital information to what we see in the real world. VR creates a completely digital world we can interact with. Both are becoming useful tools in logistics.

AR and VR are helping in these ways:

- Warehouse workers using AR glasses can see exactly where to find or place items.

- VR can train new workers safely, letting them practice in a virtual warehouse.

- Managers can use VR to “walk through” a planned new facility before it’s built.

Think about a new worker learning to operate a forklift. With VR, they can practice in a safe, virtual environment until they’re confident enough to use the real machine.

9. Green technologies

In 2025, logistics companies are using more eco-friendly technologies to reduce their impact on the environment.

Green tech in logistics includes:

- Electric and hydrogen-powered vehicles that don’t pollute the air.

- Smart systems that use less energy in warehouses and offices.

- Packaging materials that can be reused or that break down naturally.

For instance, many delivery vans in cities now run on electricity. They’re quiet and don’t produce exhaust, making deliveries cleaner and more pleasant for everyone.

10. Advanced data analytics

With all the new technologies creating lots of data, advanced analytics tools are crucial in 2025. These tools help make sense of all the information.

Advanced analytics are used for:

- Understanding customer behavior to provide better service.

- Finding ways to save money and work more efficiently.

- Making better decisions about where to put warehouses and how to route deliveries.

Imagine a system that can look at millions of deliveries and find patterns. It might discover that certain types of packages often get damaged and suggest better ways to pack them.

Conclusion

These 10 technologies are changing logistics in big ways. They’re making the movement of goods faster, smarter, and more environmentally friendly. As we look to the future beyond 2025, we can expect even more exciting changes.

For people working in logistics, learning about these technologies is important as they offer new ways to solve old problems and create opportunities for better service.

For customers, these technologies mean getting what you want more quickly and easily than ever before. Products will arrive faster, in better condition, and with less impact on the environment.